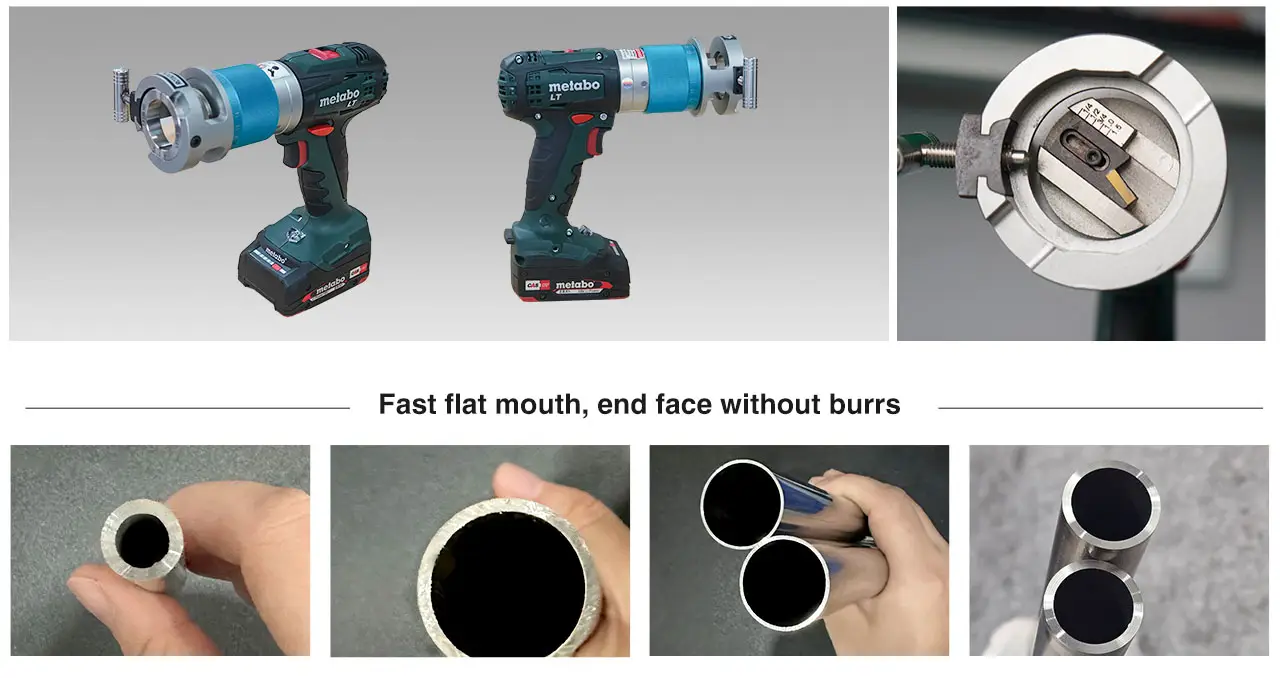

KEPUNI’s tube facing machine employs non-polluting cold-working technology to achieve flawless pipe end preparation, ensuring a flat, burr-free surface while maintaining material integrity. The fully enclosed processing environment prioritizes operator safety and process reliability, making it ideal for industries with stringent quality and safety standards.

Key Features:

Broad Material Compatibility

Machines copper, iron, aluminum, carbon steel, stainless steel, titanium alloys, and other specialty metals with equal precision.

High-Performance Metabo Motor

Driven by a Metabo industrial-grade motor, the machine delivers consistent power, torque, and stability, even for heavy-duty applications.

Cold-Working Advantage

Eliminates heat-affected zones (HAZ) and work hardening, preserving the substrate’s mechanical properties and corrosion resistance.

Enclosed Processing Chamber

A dust-tight, sealed workspace minimizes exposure to metal particles and noise, ensuring compliance with OSHA and EU safety regulations.

Compact Design with Rapid Clamping

Features a one-to-one quick-change fixture for fast, secure pipe clamping, reducing setup time by up to 50%.

Precision Feed Control

Micro-adjustable cutting depth (±0.01 mm) enables fine-tuning of material removal, ensuring consistent end face perpendicularity and surface finish.